PWI Intros PMA-Approved LED Cabin Lighting System For Cessna Citation Excel 560XL Jets

PWI Boosts US Sales Effort Adding Lance Lajara as West Coast Sales Rep

PWI LED ‘Logo Light’ Gains FAA PMA Certification For King Air And Citations

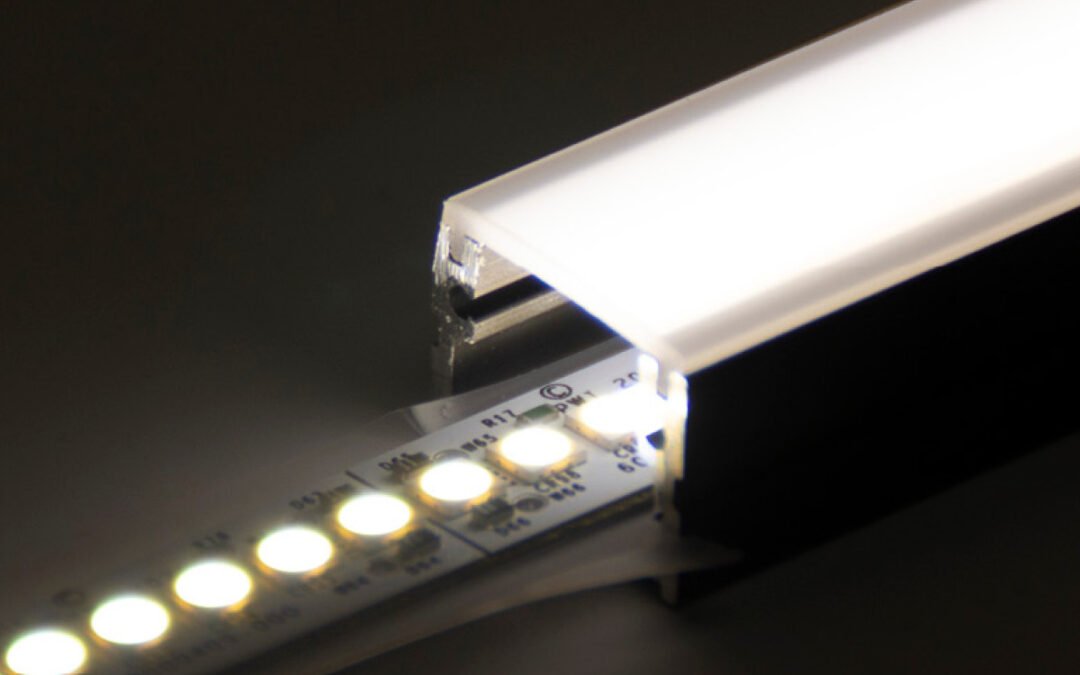

PWI Cabin LED Lighting Kits Earn PMA Approval in Citation II 550 and CJ1 525